Essco’s manufacturing capabilities continue to expand to meet the changing needs of its customers, all with a focus on helping remain competitive.

To ensure overall performance, Essco sources the highest quality raw materials, but its technicians go further by carefully checking all incoming stock for metallurgical and chemical specifications. Essco also utilizes the Rockwell hardness test method to confirm the integrity of the materials before the blades are manufactured. This quality assurance procedure identifies each blade with its raw material source.

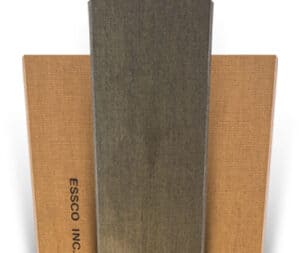

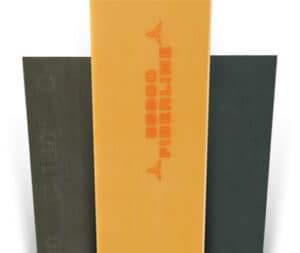

Essco’s commitment to product quality made it the first doctor blade manufacturer in the US to have an in-house blade material laminating facility. The Essco Laminates, Inc. subsidiary produces Essco’s many custom-formulated laminate grades, including the exclusive Fiberline™ family of advanced synthetics, which is the industry standard for composite blades. This capability allows Essco to fully control the quality, inventory, cost, and delivery of its laminated blades.

Every Essco doctor blade/scraper blade is parallel ground or machined for straightness to eliminate camber. Dimensional tolerances and bevel uniformity are also assured. Each blade is then hand-finished, deburred, and cleaned for optimal performance.

Material options for Essco doctor blades and scraper blades include:

Essco cotton-based blades offer economical water and fiber removal for forming sections and soft press rolls on certain paper machines.

Plastic blades provide cost-effective options for applications that require less rigidity, such as water removal.

Fiberglass blades combine excellent roll-cleaning performance with superior wear-resistance. Fiberglass blades can also incorporate custom laminates engineered to meet the specific needs of just about any application.

Carbon fiber is a leading choice for applications that require a strong, long-lasting doctor blade. Essco carbon fiber blades combine stiffness and high corrosion resistance for improved lifecycle costs.

Primarily used in tissue and creping operations, Essco metal blades are available in several alloys and hardness ranges to meet specific application requirements.

Abrasive blades offer excellent cleaning performance for oscillating applications, such as press doctor trailing positions or in the dryer section.

Filter Results

| Blade | Material | Standard Thickness | |

|---|---|---|---|

Spec 281  | Teflon, White TFE Low Friction, High Temperature (Fiberglass Reinforced Also Available) | .250" | |

Spec 285  | Virgin UHMW Polyethylene | .250" | |

Spec 285GB  | Micron-Bead-Filled UHMW Polyethylene with Extended Thermal and Wear Properties | .250" | |

Spec 285SF  | Polyethylene with Impregnated Lubricant | .250" |

Filter Results

Teflon, White TFE Low Friction, High Temperature (Fiberglass Reinforced Also Available)

Polyethylene with Impregnated Lubricant

Micron-Bead-Filled UHMW Polyethylene with Extended Thermal and Wear Properties

Sign up for industry alerts, our latest news, thoughts and insights from Essco.

All Rights Reserved.

Fill out the form below.

"*" indicates required fields